In today’s highly connected world, supply chains are at the heart of global commerce. Efficient movement of goods is vital for the health of businesses, economies, and consumers alike.

With the challenges posed by increasing consumer demands, rising transportation costs, and the complexity of global trade, companies are increasingly turning to technology—specifically Artificial Intelligence (AI)—to optimize supply chain processes.

This transformation is not only enhancing efficiency but also driving cost savings, reducing carbon footprints, and improving customer satisfaction.

In this in-depth exploration, we’ll look at how AI is revolutionizing supply chains and route optimization, making logistics smarter and more adaptable to the demands of the modern marketplace.

The Role of AI in Supply Chain Management

Supply chains are a complex web of activities, from procurement and production to warehousing, transportation, and final delivery. Traditionally, these processes have been heavily dependent on human oversight, leading to inefficiencies and delays, especially in response to unforeseen circumstances.

AI is reshaping this landscape by automating decision-making, predicting disruptions, and ensuring optimal performance through:

- Demand Forecasting: Accurate demand forecasting is crucial for maintaining the right inventory levels and reducing both stockouts and excess stock. AI-powered models use historical data, real-time trends, and external variables such as weather or economic indicators to predict demand with high accuracy.

- For instance, Amazon employs machine learning to anticipate purchase behaviors, allowing them to optimize inventory and reduce unnecessary costs.

- Supplier Relationship Management: AI helps in managing supplier relationships more efficiently by analyzing supplier performance data, predicting potential disruptions, and identifying alternative suppliers when needed. AI-driven insights into supplier reliability and risks can mitigate issues related to delays or quality.

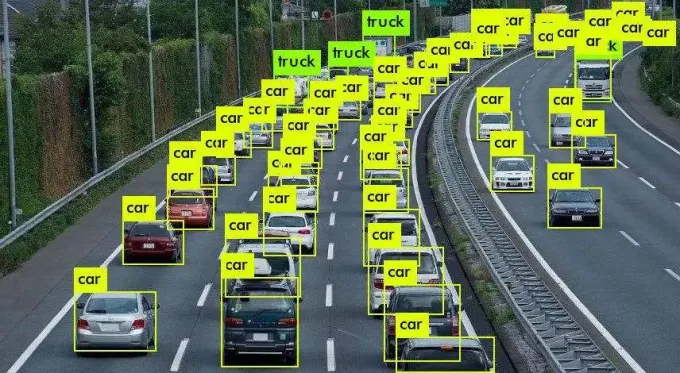

- End-to-End Visibility: AI-enabled supply chain visibility tools allow stakeholders to track goods in real time. Technologies like computer vision and IoT are paired with AI algorithms to provide real-time updates on shipments, warehouse inventory, and delivery status, ensuring better decision-making and transparency.

- Warehouse Automation: AI-driven robots and software are making warehouses smarter. Automation in picking, packing, and inventory management not only increases speed but also reduces errors. AI models, such as those used by Ocado, ensure that automated warehouses function with minimal downtime and maximum efficiency.

AI in Route Optimization

One of the most impactful applications of AI in logistics is route optimization. Transportation is a significant component of logistics, and the ability to deliver goods efficiently can have a tremendous effect on profitability and customer satisfaction.

- Dynamic Route Planning: Traditional route planning methods are static and cannot adjust easily to changes such as weather conditions, road closures, or unexpected delays. AI-based route optimization tools leverage real-time traffic data, weather forecasts, and historical patterns to determine the most efficient delivery routes dynamically. This ensures minimal disruptions and optimizes delivery timeframes.

- Predictive Analytics for Fleet Management: Predictive analytics, powered by AI, can analyze vehicle health and driver behavior to prevent potential breakdowns and improve the efficiency of fleet operations. Predictive maintenance, which schedules repairs before problems become critical, helps reduce downtime and prolongs vehicle lifespan.

- Reducing Fuel Consumption: AI-based route planning not only optimizes routes for time but also for fuel efficiency. Shorter, optimized routes and minimizing idling through AI can result in significant fuel savings, leading to reduced costs and a smaller carbon footprint. UPS, for instance, uses an AI-driven system called ORION to reduce miles driven and improve fuel efficiency across their fleet.

- Autonomous Deliveries: The use of AI is also paving the way for autonomous deliveries through drones and self-driving vehicles. These AI-powered delivery systems can significantly reduce labor costs and improve efficiency, particularly for last-mile deliveries, which often present the most expensive segment of the logistics process.

The Benefits of AI in Supply Chain and Logistics

- Increased Efficiency: AI-driven automation and optimization lead to faster processes and reduced manual interventions. This increases the overall efficiency of supply chains, allowing companies to scale without a proportional increase in labor costs.

- Cost Reduction: Efficient route planning, optimal inventory management, and reduced downtime all contribute to significant cost reductions. According to a study by McKinsey, companies using AI in their logistics operations have reported cost savings of up to 20%.

- Enhanced Customer Experience: Accurate demand forecasting, real-time delivery updates, and prompt deliveries all help improve customer experience. AI ensures that customers are kept informed and that their orders arrive within promised timeframes.

- Greater Resilience: With AI-driven insights, supply chains become more resilient to disruptions. Machine learning models can predict risks such as supplier delays, weather disruptions, or changes in consumer behavior, allowing companies to adapt and respond proactively.

Challenges to AI Adoption in Supply Chains

While AI presents numerous benefits, companies face certain challenges in its adoption:

- Data Quality and Availability: AI is only as effective as the data it processes. Many logistics companies face issues with fragmented or poor-quality data that hinder AI’s potential.

- Initial Implementation Costs: The implementation of AI in supply chains requires an upfront investment in software, hardware, and training. For small and medium-sized enterprises, these costs can be a significant barrier.

- Talent Shortage: Skilled professionals who understand both logistics and AI are crucial for successful implementation. There is a growing demand for data scientists and AI specialists in the logistics field, but the talent pool is still limited.

Future Trends in AI for Supply Chains and Logistics

The use of AI in logistics is expected to evolve significantly in the coming years. Here are a few trends to watch:

- Collaborative Robots: In warehouses, AI-driven collaborative robots (cobots) will become more prevalent. These robots are designed to work alongside human workers, boosting efficiency while maintaining flexibility.

- AI-Driven Predictive Risk Management: AI will be used to predict supply chain disruptions and assess potential risks due to geopolitical, environmental, or economic factors. This will enable companies to develop more resilient supply chain strategies.

- End-to-End AI Integration: As AI continues to mature, we can expect deeper integration across the entire supply chain. This will result in seamless AI-driven decision-making, from supplier selection to delivery and customer feedback.

- Personalization and Customer-Centric Logistics: AI will enable logistics companies to offer more personalized services, including customized delivery times and tailored shipping options based on customer preferences.

Conclusion

AI is revolutionizing supply chains and route optimization, transforming an industry that has traditionally relied on human intuition and experience into a data-driven, automated powerhouse.

The use of AI in logistics is driving increased efficiency, cost reductions, and improved customer experiences. Despite challenges in data quality, cost, and expertise, the potential benefits are driving rapid adoption across industries.

As companies continue to invest in AI, the logistics industry will become smarter, more resilient, and increasingly sustainable. In this rapidly evolving landscape, those who embrace AI today will be the leaders of tomorrow’s supply chain innovations.

Also Read

How digital twins are transforming real-time tracking and predictive maintenance

Benefits of Blockchain Technology in Logistics Industry