Munich, January 29, 2026 – Intralogistics is undergoing a quiet but profound transformation.

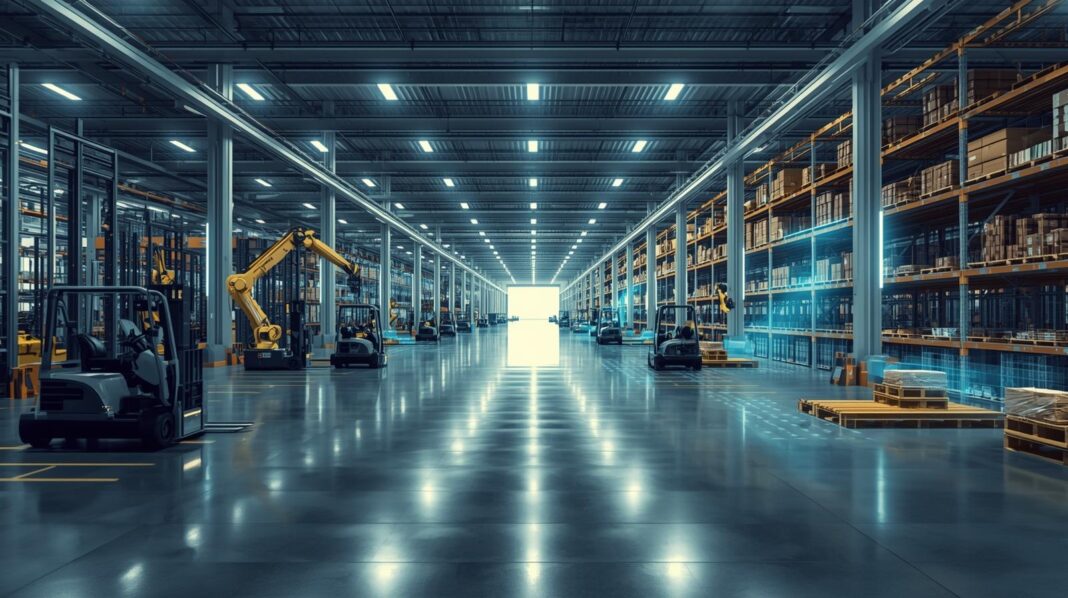

What was once driven by fixed rules, manual planning, and reactive decision-making is now increasingly shaped by artificial intelligence.

As the industry looks ahead to LogiMAT 2026, AI has emerged as the defining force behind smarter warehouses, optimized material flows, and resilient supply chain operations.

Under our Road to LogiMAT series, The Africa Logistics Blog examines how AI is moving from concept to critical infrastructure—reshaping intralogistics across warehousing, transport management, automation, and data analytics, with lessons that resonate strongly for African logistics markets.

AI: From Innovation Buzzword to Operational Backbone

Artificial intelligence has rapidly become a cornerstone of digital transformation strategies in logistics. Yet adoption remains uneven.

Research by IDC and SAS indicates that while many organizations recognize AI’s potential, gaps in IT infrastructure, data governance, and cybersecurity continue to limit trust and large-scale deployment.

LogiMAT 2026 offers a glimpse into how the industry is addressing these challenges. According to LogiMAT Exhibition Director Michael Ruchty of EUROEXPO Messe- und Kongress-GmbH, automation and AI have evolved from emerging trends into decisive competitive factors.

“When combined with other digital technologies, AI enables end-to-end visibility and continuous optimization of intralogistics processes,” Ruchty notes.

“Across all industry segments, exhibitors are demonstrating how integrated AI applications are delivering measurable efficiency gains.”

Smarter Software, Smarter Warehouses

The most immediate impact of AI is visible in warehouse management and planning software.

In Hall 4 at Messe Stuttgart, leading software providers are showcasing how AI can turn fragmented operational data into real-time intelligence.

Logistics Reply is presenting GaliLEA Dynamic Intelligence, a platform designed to accelerate AI adoption by simplifying the creation and deployment of AI agents.

Using a visual interface, logistics teams can configure agents that pull data from multiple systems, identify anomalies, and support operational decisions in real time—reducing technological dependency while expanding automation potential.

Meanwhile, Inform’s Demand AI focuses on one of intralogistics’ most persistent challenges: demand uncertainty.

The cloud-based solution delivers continuous AI-driven forecasts for existing products while generating reliable demand projections for new items.

By integrating directly into existing ERP and planning systems, it enables faster, data-driven decisions without complex implementation projects.

PSI Software builds on this approach with the latest generation of its PSIwms AI platform, featuring an integrated Batch AI module.

By combining rule-based logic with AI-supported batch formation, the system optimizes picking strategies, reduces walking distances, improves throughput, and lowers operational costs—demonstrating how incremental AI improvements can deliver significant efficiency gains.

AI-Driven Transport Inside the Warehouse

Beyond forecasting and picking, AI is increasingly shaping how goods move within logistics facilities. Transportation management systems enhanced by AI are transforming intralogistical transport planning, execution, and monitoring.

Brabender Solutions from Switzerland showcases a TMS with AI-supported feedback and intelligent document extraction through its DocKI document management system, streamlining internal workflows and reducing administrative friction.

Flexus integrates AI with digital twin technology in its FlexGuide4 system, enabling real-time simulation of forklift fleets, tugger trains, and autonomous vehicles. By proactively identifying bottlenecks and safety risks, operators can optimize workflows before disruptions occur.

Sustainability and electrification also feature prominently. Pass Logistics Solutions uses AI-driven route planning to connect planners, drivers, and end customers, while calculating optimized routes specifically for electric vehicles—balancing efficiency, energy consumption, and service reliability.

Where AI Meets Automation and Robotics

Material handling technology is another area where AI is redefining operational performance. Automation providers at LogiMAT 2026 are demonstrating how self-learning systems can adapt dynamically to changing operational conditions.

Element Logic introduces eOperator, an AI-based software solution that integrates robotic piece picking into AutoStore systems, enabling higher throughput and greater flexibility in order fulfillment.

Advasolutions takes a holistic approach, promoting the concept of a self-learning warehouse. Its AI-based functions—ranging from quality control to route planning—connect inbound logistics, storage, picking, and shipping into a single adaptive system capable of handling diverse product sizes, shapes, and packaging formats.

One of the most comprehensive AI platforms on display comes from Knapp. Marketed as the “first AI platform for smart value chains,” Knapp Brain consolidates AI-based solutions across forecasting, order fulfillment, and last-mile delivery.

Supported by the KiSoft software suite, the platform enables real-time coordination between warehousing, transport, and delivery—optimizing routes, calculating delivery windows dynamically, and factoring in traffic conditions, load volumes, and customer preferences.

Lowering the Barrier to AI Adoption

A notable trend at LogiMAT 2026 is the growing emphasis on low-threshold AI applications—solutions designed to deliver value without requiring advanced data science expertise.

In the AIDC segment, Keyence presents AI-enabled code readers capable of reliably identifying damaged or complex barcodes in high-speed sorting and picking environments.

Imago Technologies demonstrates AI-based vision systems that detect process deviations early, helping operators prevent downtime and quality issues before they escalate.

AI is also gaining traction in automated guided vehicle environments. Continua Systems showcases its Automation Insights platform, which applies AI-supported analytics to AGV fleets—identifying patterns, predicting potential failures, and improving transparency in highly automated operations.

What This Means for Africa’s Logistics Future

For logistics operators across Africa, the innovations highlighted on the Road to LogiMAT carry particular significance. Faced with infrastructure limitations, rising costs, and growing customer expectations, AI offers a powerful tool to leapfrog traditional inefficiencies.

AI-driven forecasting can help manage demand volatility, while intelligent warehouse and transport systems can improve asset utilization and service reliability—even in constrained environments.

Crucially, the shift toward modular, cloud-based, and low-threshold AI solutions makes advanced intralogistics technologies more accessible than ever before.

Small Data Gains, Big Competitive Advantages

As LogiMAT 2026 approaches, one message is increasingly clear: AI in intralogistics is not about radical disruption, but about continuous optimization.

Small, data-driven improvements—better forecasts, smarter routes, faster picking—compound over time to deliver significant competitive advantages.

“AI is not rocket science,” concludes Ruchty. “It optimizes material flows at multiple levels, often through details that make a small but decisive difference.”

For the global logistics industry—and for Africa’s rapidly evolving supply chains—the Road to LogiMAT shows that the future of intralogistics is intelligent, connected, and firmly driven by artificial intelligence.

FREQUENTLY ASKED QUESTIONS (FAQ)

Where is LogiMAT 2026?

LogiMAT 2026 will take place at Messe Stuttgart, Germany. The exhibition centre is located directly next to Stuttgart Airport and is one of Europe’s most important venues for international trade fairs.

When exactly is LogiMAT 2025?

LogiMAT 2025 was held from 11–13 March 2025, at Messe Stuttgart, Germany.

What is the exhibition in Germany in March 2026?

The major international logistics exhibition taking place in Germany in March 2026 is LogiMAT 2026, the leading trade fair for intralogistics solutions, process management, and supply chain optimisation.

Is LogiMAT open to the public?

LogiMAT is primarily a B2B (business-to-business) trade show focused on intralogistics solutions, not an event designed for the general public. It is intended for industry professionals, decision-makers, and trade visitors looking to source solutions, rather than general consumers.

Also Read

The rise of Artificial Intelligence in shipping

Africa Ports & Terminal operations in the age of artificial intelligence